Products

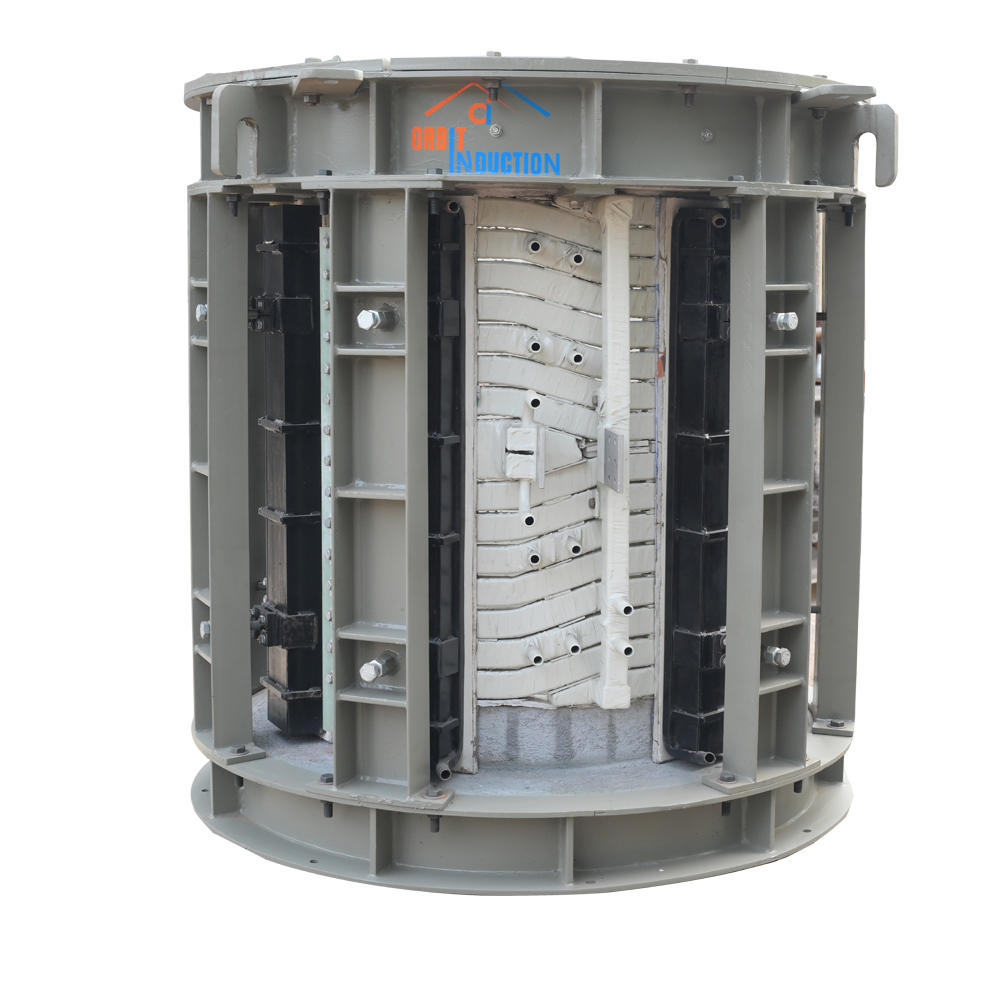

Steel Casting Credle

Steel Casting Credle

A steel casting cradle is a specialized structure or platform designed to hold the molds or crucibles containing the steel charge during the melting and casting process. The cradle provides support and stability to the molds as the molten steel is poured into them, ensuring a safe and controlled casting operation.

The typical process for steel casting using an induction furnace and cradle involves the following steps:

- Charging: The steel charge, which may consist of scrap steel or other raw materials, is placed inside the crucible or mold.

- Melting: The steel casting cradle is positioned under the induction furnace's coil, and the furnace is activated to start the melting process. The high-frequency alternating current generates a rapidly changing magnetic field that induces eddy currents in the steel charge, causing it to heat up and melt.